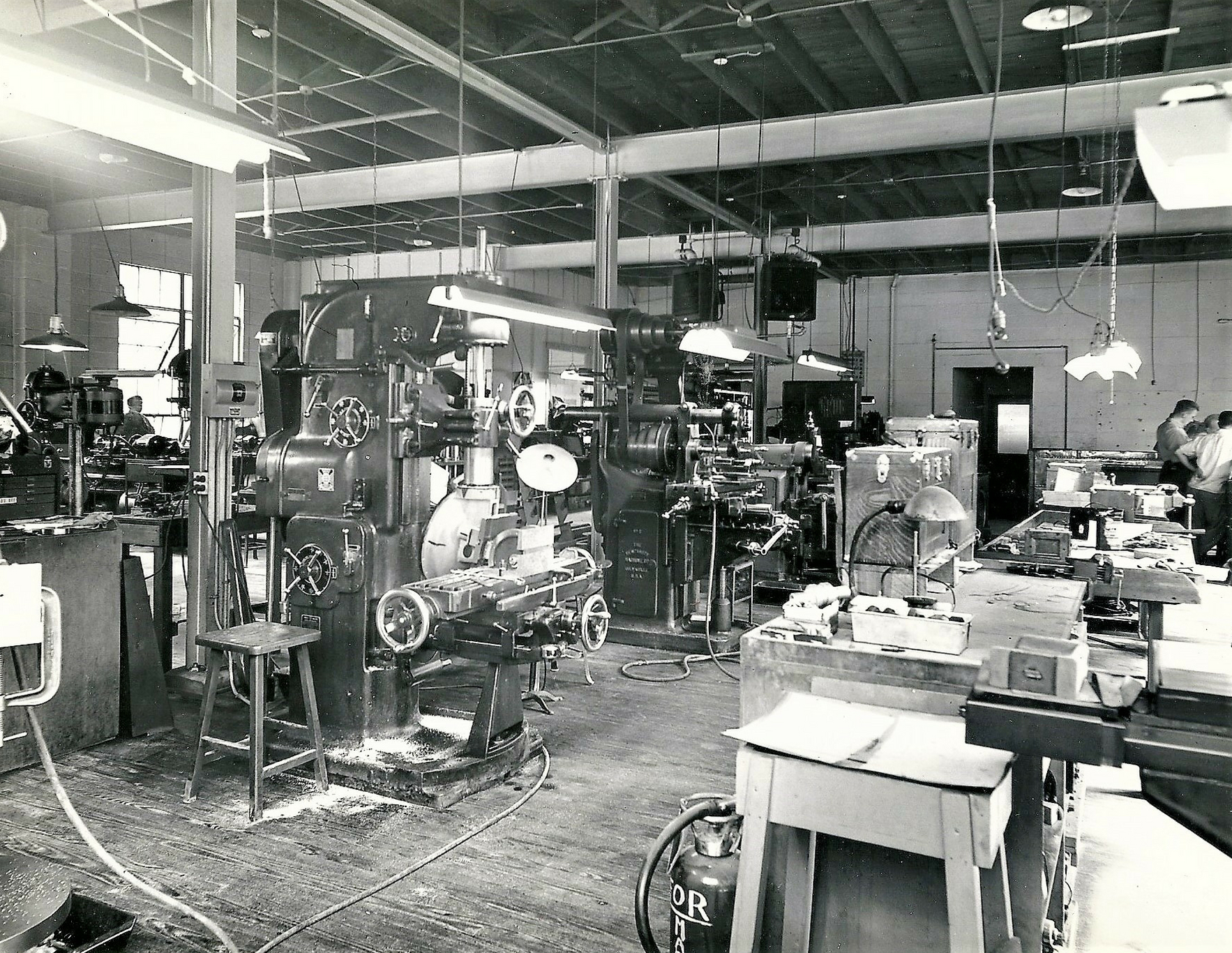

I have often been asked how a History and English major came to be a restorer of some of the World’s finest racing cars. I have written briefly about my father who was an extreme influence on me. When I was 10 years old I went to work for the summer at his company the FT Griswold Mfg. Company in Wayne Pennsylvania. To do this I had to apply for my Social Security card. I was paid real wages albeit very little, but it was a start to a working life that was to pay real dividends later on. Dad had a high precision machine shop and we could make almost anything to a very high standard.

A lot of the work was for the Department of Defense, things like alignment gauges for Patton tank barrels and the propeller heads for twin rotor Paisecki helicopters that were used extensively in the Korean War. I used to go to work every day with dad and his shop manager Phil Yanni would give me some menial cleaning job to keep me busy and out of the way. The men that worked for dad were really kind to me and could see that I had a consuming passion for all the machines and how they worked. Eventually, they started to give me some simple machining projects to get a real feel for machining.

This would happen when a certain machine was free and not scheduled for use in the near future. This was great fun. I discovered that I really loved making things.

After a few years as a virtual clean up boy I was given the job to engrave long measuring scales very much like a yardstick but longer and to very high precision.

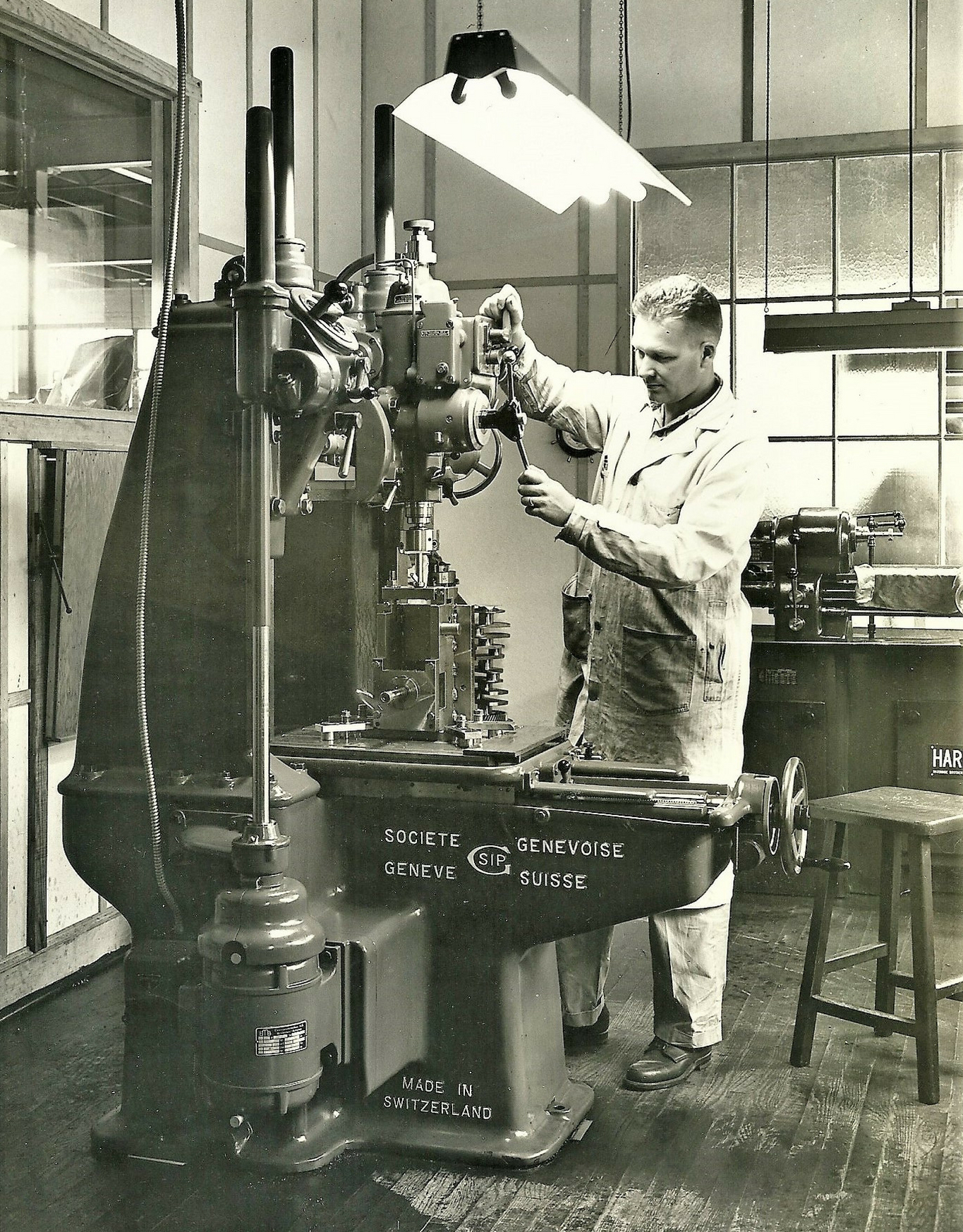

It could take up to 8 hours or more to do each one and during this time I had to use a jeweler’s glass to watch the point of the cutting tool in case it would get blunt and cut too wide a line. When this happened I would have to shut down the machine and take the tool bit and place it in a grinder and re sharpen the cutting point. The room where the SIP engraving machine was, was kept at a constant temperature so the steel wouldn’t grow or contract and ruin the accuracy of the finished piece. These measuring scales were then read by an optical reader and were extremely precise. This was the second school I participated in whilst growing up.

In addition to this, there were always interesting cars around that needed attention. All dad’s friends were always bringing their sports cars around for this or that. It was the early years and these cars were almost unknown and few knew how to fix them except my father. I often was given a simple task to perform. I loved this and the fact that I was trusted. I also learned a lot about how to spot the problem and diagnose them. In a short time, I became a very accomplished mechanic to add to my machining qualification.

12 years later after University when I opened my first racing preparation shop, I was able to draw on the vast experience I had working all those summers in Wayne Pennsylvania at the F.T. Griswold Mfg. Co.

When I decided to really develop my restoration business I had a real advantage especially for rebuilding racing engines like those fitted to Maserati. These engines had no gaskets and used gears to drive the moving parts. When these cars came to me they were in a terrible state; forgotten no longer competitive racing cars that were totally worn out and needing everything. These cars needed a full machine shop and not a box of mechanic’s hand tools to give them their renaissance. I was in an ideal position to take the lead and establish myself throughout the world for this type of work.

My true regret was that my father died before I got started in business. He would have been a real asset to me and to this day I still think of all that he taught me.